Invention Summary:

Brittleness of glass has been perceived as its gravest handicap in the glass technology space. While the glass industry has always strived to design a "hard" and "crack-resistant" glass, it has been generally accepted by glass scientists that it is hard to achieve both these properties in the oxide glasses. Recent literature in the glass space revealed that a hard and crack resistance glass can be obtain using a Al2O3 – SiO2 binary system. However, to synthesize such composition of glass requires high melting temperatures (>1800 ֯C) and thus the synthesized glasses can only be produced in small shapes and dimensions. It is therefore desirable to identify compositions that are intrinsically resistant to formation of cracks without losing the hardness. It is further desired that such glasses be manufactured under a cost-effective manner.

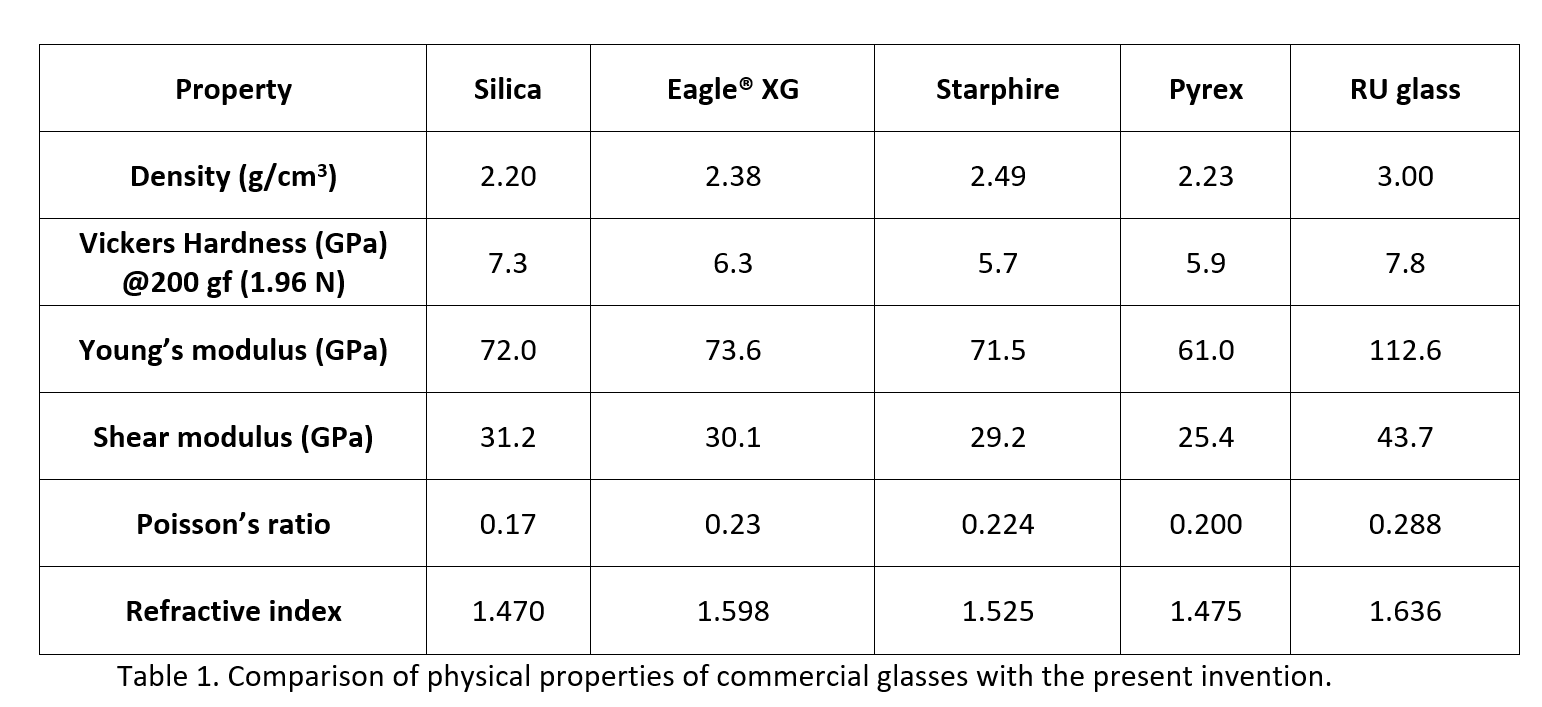

Rutgers Researchers have designed and developed a novel aluminoborosilicate based glass (RU glass) that is hard and crack resistant (up to 26.7 N or 2.7 kgf). Further, the glass exhibits high Young’s modulus, optical transmittance (≥88%) and can be synthesized using conventional glass manufacturing infrastructure.

Advantages:

- High hardness and crack resistance

- High Young’s modulus

- Easily synthesized with existing glass production infrastructure

Market Applications:

- Safety/Security glass industry

- Automobile industry

- Military applications

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration.